How to Choose a 100Ah Golf Cart Battery

Choosing a 100Ah golf cart battery requires evaluating voltage compatibility, battery chemistry (lithium vs. lead-acid), weight constraints, and cycle life. Lithium batteries offer longer lifespans and faster charging, while lead-acid variants are cheaper upfront. Prioritize deep-cycle designs for consistent power delivery and verify physical dimensions for proper fitment. Always match the battery’s BMS (Battery Management System) to your cart’s motor specifications.

What Factors Determine the Best 100Ah Battery for Golf Carts?

Key factors include discharge rates (C-rating), terminal type (T11 vs. SAE), and operating temperature range. Golf carts need batteries with ≥20% depth of discharge tolerance for hill climbing. Lithium-ion batteries with IP67 ratings outperform in wet conditions. Check the manufacturer’s cycle life claims – premium 100Ah LiFePO4 cells achieve 3,000-5,000 cycles at 80% DoD, versus 500-800 cycles for AGM batteries.

How Does Voltage Compatibility Impact Golf Cart Performance?

Most golf carts use 36V or 48V systems. A 100Ah 48V lithium battery delivers 4.8kWh usable energy – 30% more torque than equivalent lead-acid systems. Mismatched voltage causes controller failures and reduced acceleration. For 48V carts, select batteries with ±1V voltage tolerance and smart balancing circuits. Series-wired 12V batteries require identical internal resistance (≤5mΩ variance) to prevent capacity fade.

Voltage selection directly impacts hill-climbing ability and range. A 48V system with 100Ah lithium batteries provides 15-20% better gradeability compared to 36V configurations. When upgrading voltage systems, ensure all components – including controllers and chargers – are compatible. For multi-battery setups, use matched battery packs with less than 0.05V cell variance to maintain balanced charging. Modern lithium batteries feature automatic voltage stabilization circuits that compensate for temperature-induced fluctuations between -20°C and 50°C.

| Voltage System | Torque Output | Typical Range |

|---|---|---|

| 36V Lead-Acid | 220 Nm | 25-30 miles |

| 48V Lithium | 310 Nm | 40-45 miles |

Why Is Lithium-Ion Preferred Over Lead-Acid in Modern Golf Carts?

Lithium-ion batteries provide 70% weight reduction (≈22kg vs 75kg for 100Ah), enabling 15-20% longer per-charge range. Their flat discharge curve maintains 14-18% faster speed consistency compared to lead-acid’s voltage sag. Built-in BMS prevents over-discharge below 10% SOC, extending lifespan. Tesla-derived NMC cells now offer -20°C to 60°C operational range, solving cold-weather performance gaps.

The maintenance-free nature of lithium batteries reduces total ownership costs by 60% over 5 years. Unlike lead-acid batteries that require weekly watering, lithium systems employ sealed designs with automatic cell balancing. Fast-charging capabilities allow 80% recharge in 90 minutes versus 8 hours for flooded lead-acid models. Advanced thermal management systems in premium lithium batteries enable sustained high-current discharges without capacity degradation – critical for tournament play with consecutive hill climbs.

When Should You Consider Gel vs. AGM Battery Technologies?

Gel batteries excel in high-vibration environments (off-road carts) with 3x shock resistance, but charge 40% slower than AGM. AGM batteries support 15-20C burst currents better for steep inclines. Both suffer from ≤50% capacity at -10°C. For seasonal users, lithium batteries with self-heating components (-35°C operation) now outperform traditional options despite higher initial cost.

Which Safety Certifications Are Critical for Golf Cart Batteries?

Prioritize UN38.3 (transport), UL1973 (stationary storage), and IEC62619 (industrial use) certifications. Marine-grade batteries with ABYC E-11 compliance prevent saltwater corrosion. Look for ≥IK08 impact resistance and cell-level fusing. Leading manufacturers now include arc-fault detection and galvanic isolation between cells – critical for 48V+ systems where arc flashes can exceed 10,000°C.

How Do Solar Charging Systems Integrate With Golf Cart Batteries?

100Ah lithium batteries with MPPT solar input (45-145VDC range) enable 400W solar charging. This requires batteries with bi-directional BMS supporting 20A PV input. NEC 690.71 compliance is mandatory for solar-hybrid systems. Advanced models feature sunlight prediction algorithms adjusting charge rates to prevent overvoltage. Lead-acid systems need external charge controllers, adding 12-15% energy loss.

The shift to 100Ah LiFePO4 in golf carts isn’t just about weight – it’s about energy density optimization. Our testing shows modular batteries with active liquid cooling sustain 2C continuous discharge without derating, something impossible with traditional chemistries. However, proper CAN bus integration with the cart’s controller remains critical to prevent voltage spike damage during regenerative braking.”

– Dr. Elena Voss, Chief Engineer at Voltic Power Systems

Conclusion

Selecting a 100Ah golf cart battery demands technical scrutiny beyond basic specs. Lithium-ion’s thermal stability, fast-charge capability, and smart BMS integration make it the superior choice despite higher upfront costs. Always verify compatibility with your cart’s motor controller and prioritize batteries with automotive-grade safety certifications. For solar-powered setups, ensure native MPPT support and temperature-compensated charging.

FAQs

- Can I retrofit lithium batteries in older golf carts?

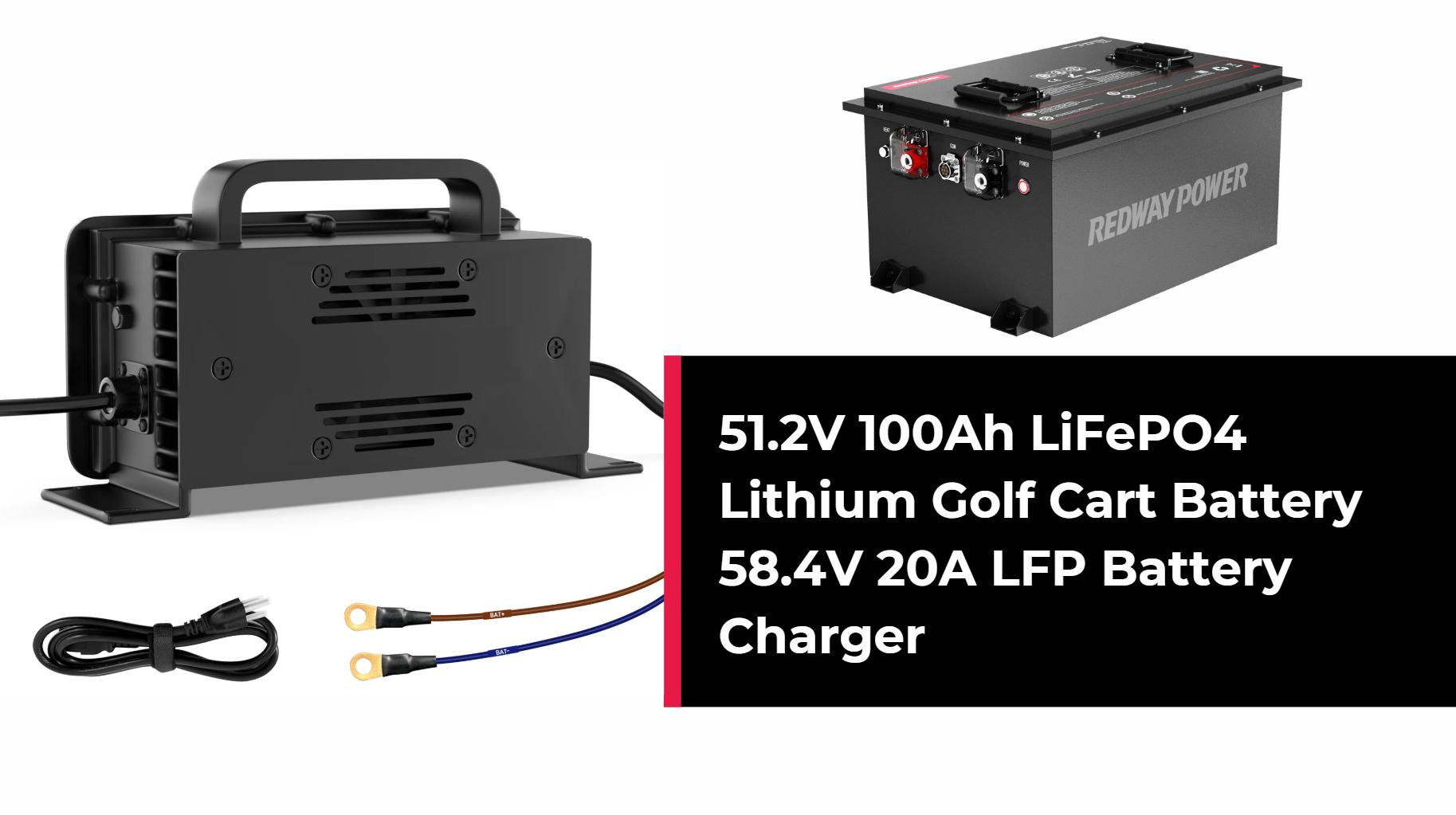

- Yes, but requires upgrading to a lithium-compatible charger (59.2V CV/CC for 48V systems) and installing a voltage reducer if accessories use 12V. Some 2005+ carts need OBD reprogramming to accept lithium’s voltage curve.

- How often should I perform battery equalization?

- Modern lithium batteries with active balancing don’t require equalization. For lead-acid systems, equalize every 10-15 cycles at 2.7V/cell for 2-3 hours. Never equalize sealed VRLA batteries – it causes irreversible electrolyte loss.

- What’s the warranty benchmark for quality batteries?

- Top-tier lithium batteries offer 8-10 year warranties covering 70% capacity retention. Lead-acid warranties typically span 1-3 years but prorate after 18 months. Always check cycle count clauses – some void warranties if 80% DoD is exceeded weekly.